Paste Application Systems

As manufacturer and supplier of paste application systems, we offer complete solutions from one hand.

We have been on the market since 1981 with our high-pressure spray guns (HDP-I, HDP-II, Wido-Spray) and our low-pressure spray guns (PERPLEX-I and PERPLEX-II) and we are strengthened in our work by our customer satisfaction.

We are the right contact for you if you need a solution from the tank to the control and monitoring (if desired also a PLC control) of the Paste Application System – with liquid or solid paste.

We have designed our high pressure spray guns to operate all sizes of polishing and buffing wheels. The liquid polishing compound will be shot with high pressure (30 to 40 bar) deep into the buffing wheel at freely selectable intervals, so that the paste is not uselessly lost due to the centrifugal force of the buffing wheel. An outlet pressure of 4 – 6 bar is completely sufficient for this.

Our low-pressure spray guns apply liquid polishing compound or grinding oil to the workpieces in a continuous process. A variation of the spray pattern is achieved by the selection of the spray nozzles (2-hole, 4-hole, etc.) and a finer adjustment of the atomization process is made possible by the number of air connections of the spray guns.

We also distribute and supply spraying systems of Westberg Dosiertechnik GmbH

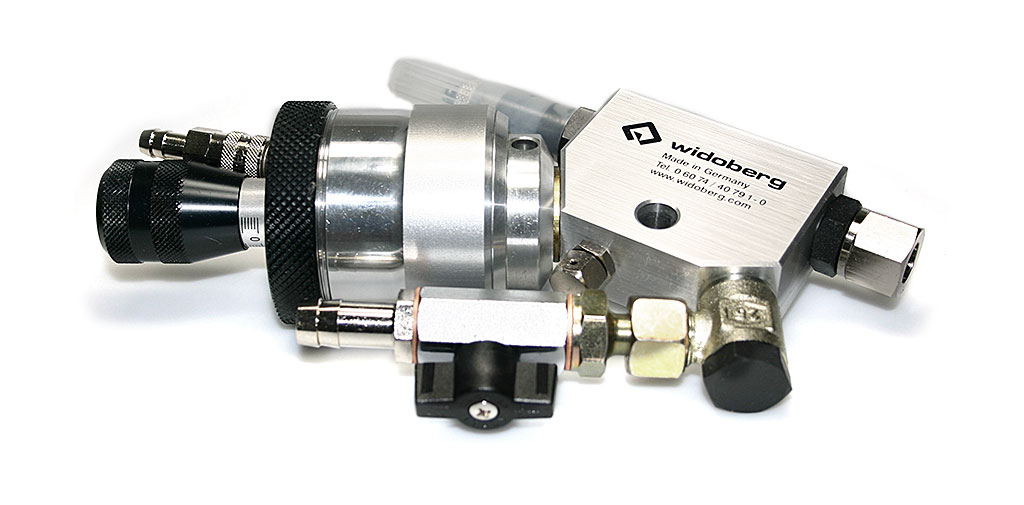

- High pressure spray gun WIDOSPRAY-2010

- Universal high pressure spray valve UHS

- Spare parts WIDOSPRAY-2010

- Spare parts UHS

Do you use solid paste? With our solid paste application system type WPZ we have the ideal solution for you.

Contact us, our experts will be happy to help you.

Hight-Pressure Spray Guns

Our models HDP-I and HDP-II are used for polishing and buffing wheels with a diameter up to 500 mm. The HDP-II is the follow-up model of the HDP-I, which is no longer produced, but we always have all spare parts in stock.

Downloads HDP-II & HDP-II Spezial

Downloads HDP-I

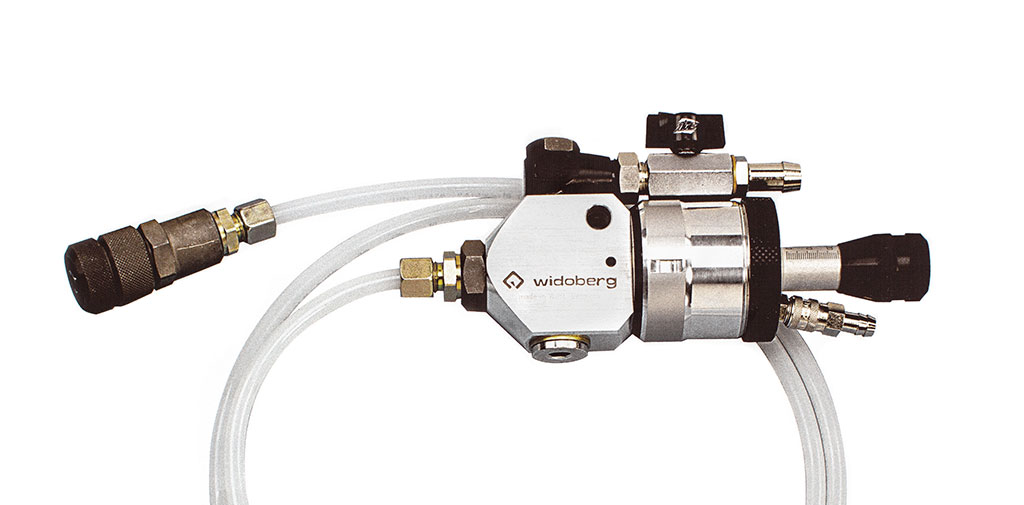

WIDO-SPRAY

WIDO-SPRAY is used for polishing and buffing wheels with a diameter of more than 500 mm – spray volume / shot 0.2 – 6 cm³. It brings the polishing emulsion into the buffing wheel with less pressure and wets a larger surface. A big advantage of the WIDO-SPRAY is that it can be equipped with our monitoring system, which checks whether the gun has fired paste or not – electronically monitored for fully automated production.

Both systems the HDP-II and the WIDO-SPRAY can be equipped with a flexible spray head. This means that the spray head is connected to the gun body by a hose and can be positioned even at hard-to-reach places on the workpiece to be polished.

Downloads WIDO-SPRAY & WIDO-SPRAY Spezial

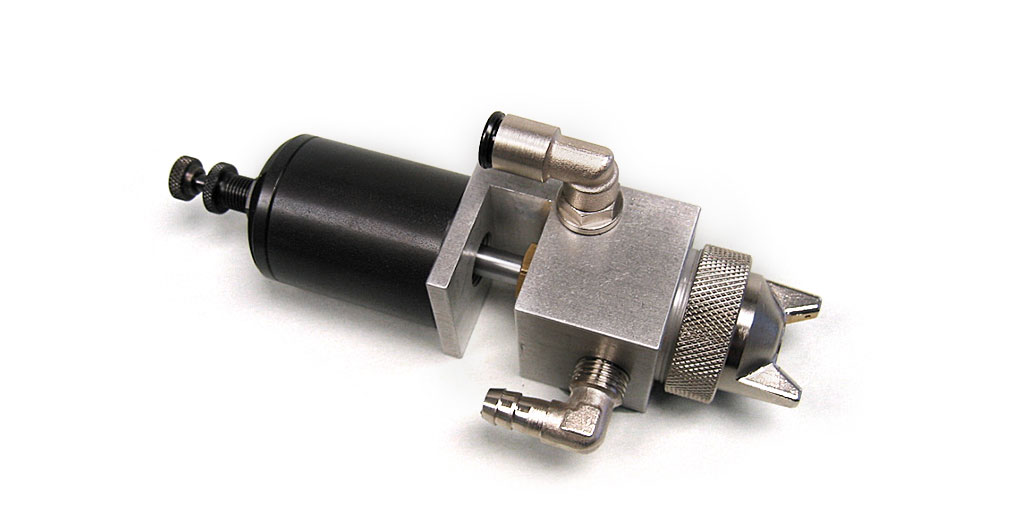

Low-Pressure Spray Guns

In addition to our high-pressure spray guns (HDP-II and WIDO-SPRAY), we round off our product portfolio with our low-pressure spray guns PERPLEX I and PERPLEX II.

With the PERPLEX models, polishing emulsion or grinding oil is continuously applied to the workpieces. The respective spray pattern can be influenced by the selection of the nozzle (2-hole, 4-hole, etc.). The only difference between the PERPLEX-I and the PERPLEX-II is that the PERPLEX-I has one air connection and the PERPLEX-II has two air connections. With the PERPLEX-I, the opening and closing of the needle and the atomization process are combined in the air connection, while with the PERPLEX-II, the opening of the needle and the atomization process are separated from each other by the two air connections and thus a finer adjustment of the atomization process is possible.

Downloads PERPLEX-I & PERPLEX-II

We are proud to offer our proven and high-quality application systems for almost 40 years and many years of customer satisfaction encourage us in this.

FAQs

With this system, grinding and polishing paste is applied to polishing and buffing wheels. Liquid paste is applied to the buffing wheels by using high-pressure spray guns and solid paste bars will be applied by a solid paste application system (pneumatic or electrical).