Surface Finishing Vibratory Systems

Universal and Economical – Ideal for Large Quantities

We offer you a complete solution from vibratory grinding to drying and process water treatment.

We would be happy to assist you in choosing the right system and the required processing equipment. We also offer you the option to test your workpieces with our systems in Dietzenbach and you will receive a test report where you can find out which machine, process equipment and grinding media we have used to process your workpieces.

We have bowl vibratory machines that can be used universally for a variety of workpieces and machining targets, trough vibratory machines that are used for vibratory grinding of medium-sized and large workpieces, and centrifugal grinding systems that are characterized by extremely high machining intensity and whose grinding performance is up to 10 times higher compared to the other vibratory machines.

We are going to find the best solution for you and we are happy to advise you.

Circular Vibrators

RA Circular Vibrators

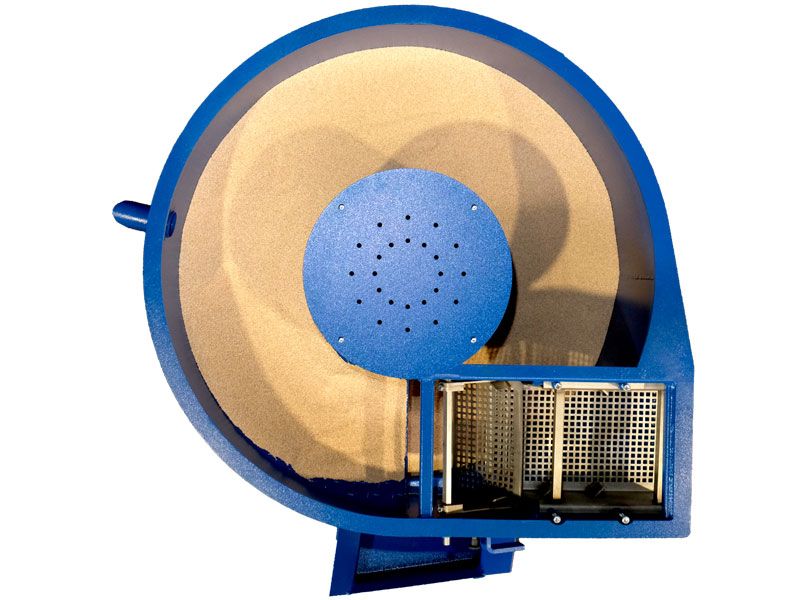

Deburring, rounding or polishing: RA rotary vibrators are universal slide grinding machines that can be used for a wide range of applications. They offer high grinding performance and impress with their ease of use combined with high reliability. Thanks to numerous options, the machine can be configured precisely to meet the requirements.

RA round vibrators are particularly suitable for processing bulk goods in large quantities. The workpieces are reliably guided onto the built-in sieve surface thanks to the gently rising container bottom. The large sieve surface with tangential outlet ensures reliable workpiece separation and offers the option of using magnetic separators.

Application Areas

-

Vibratory grinding and polishing of bulk goods in large quantities

-

Rust removal, descaling, deburring, rounding of components

-

Processing of various materials (aluminum, steel, stainless steel, plastic, …)

Technical Details

-

Round working container with an evenly and gently rising container bottom

-

Drop step for separating stuck workpieces (optionally a flowing drop step available for sensitive workpieces)

-

Highly wear-resistant, hot-cast special polyurethane protective coating for maximum service life

-

Low-maintenance and powerful vibration exciter motor with unbalances that can be adapted to the process (optionally available with adjustable unbalances for automatic ramp exposure)

-

Pneumatic flap integrated in the container for separating the workpieces

-

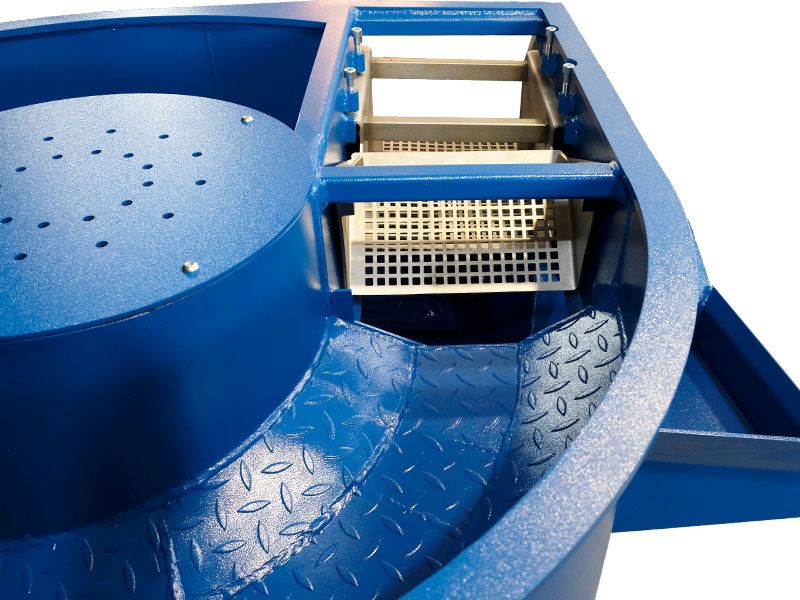

Tangential component discharge with large sieve area

-

Quick-change sieve plates

-

Modular system for the use of different sieve plates and separation systems (reverse separation, magnetic separation, …)

-

Integrated process water supply concept with exchangeable drainage sieve

-

Universal attachment option for adding numerous delivery chutes

-

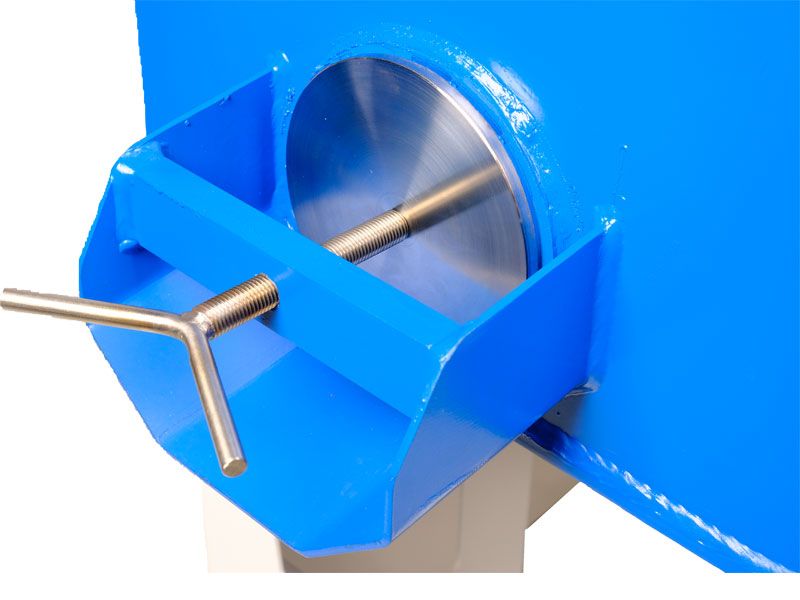

Drain opening for quick changing of grinding tools

-

Easily accessible service openings

-

Possibility of interlinking the system in a system park (interlinking with a rotary dryer, conveyor belts, rinsing systems, …)

Accessories RA Circular Vibrators

-

Ramp exposure through a built-in “reverse gear” (automatically adjustable imbalances of the vibration motor)

-

Frequency-controlled drive with variable speed control

-

PLC controlled electrical switchgear for partially and fully automated plant operation

-

Circumferential triangular profile to reduce component build-up on the container wall

-

Different fall step variants (step, ramp)

-

Sound insulation concepts (sound insulation covers, soundproof cabins)

-

Various separating systems for separating material and grinding tools (magnetic separators, reverse separation, scrapers, drop steps, …)

-

Dosing systems for process media and additives (compounds, flocculants, …)

-

Extended process water management concepts (ring showers, distributor nozzles, rinsing systems, washing nozzles, backwash systems, …)

-

Further special accessories (on request)

Technical Data

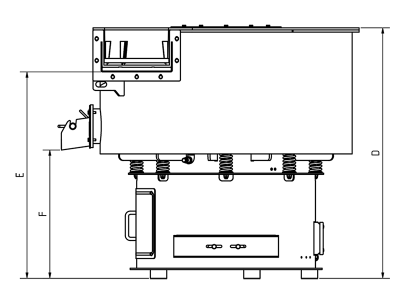

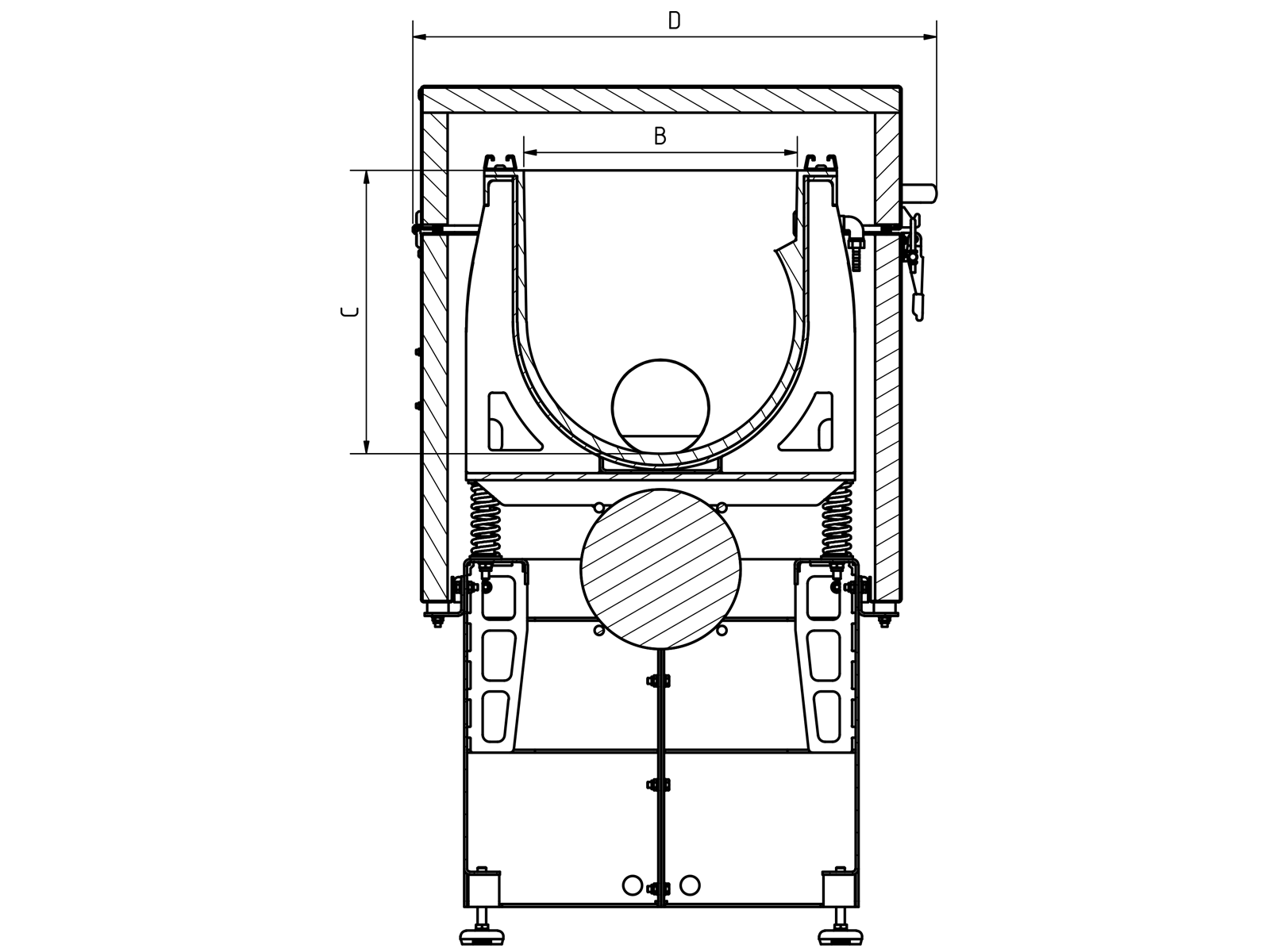

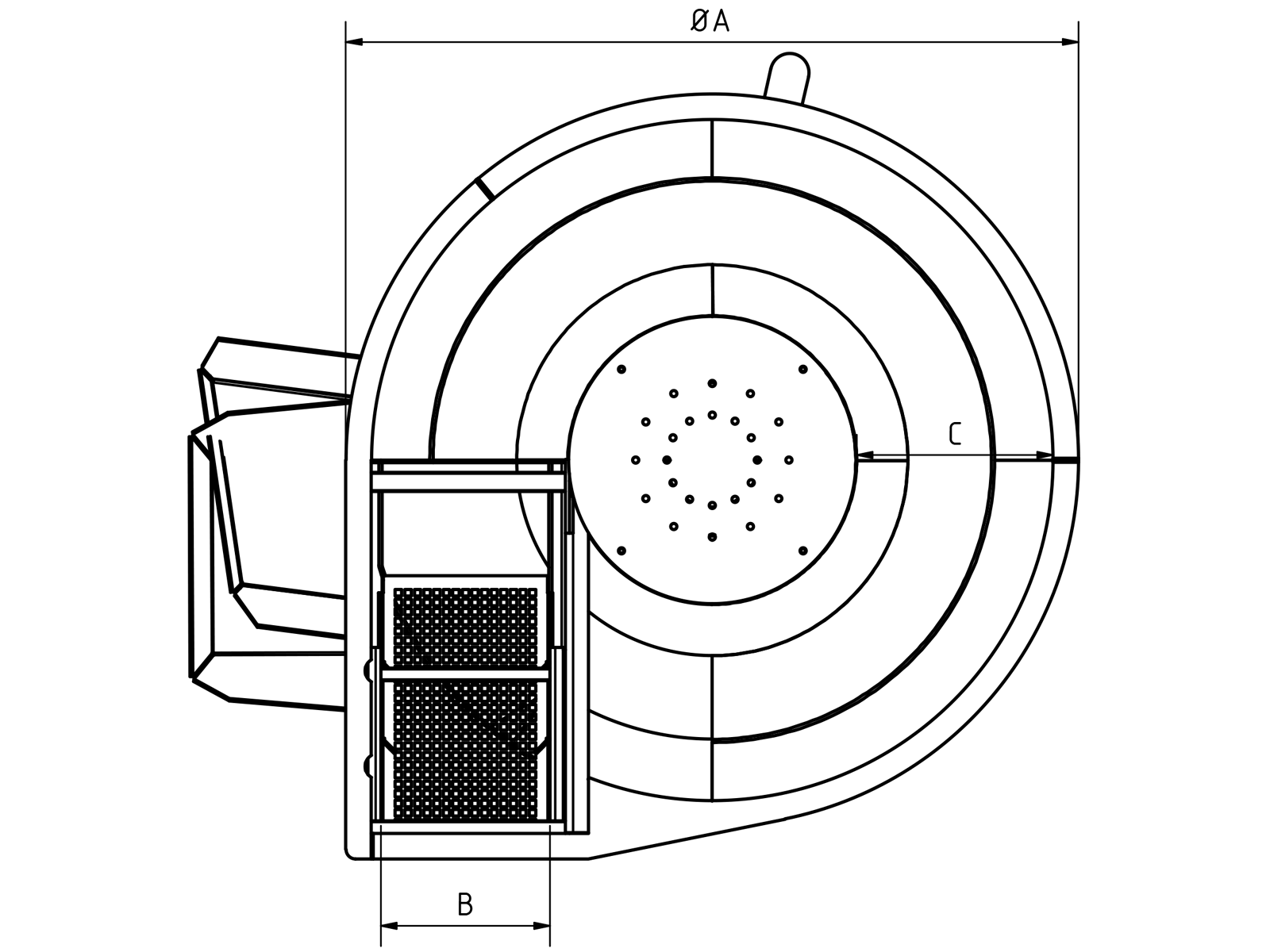

| RA06 | RA11 | RA16 | RA21 | RA31 | RA41 | RA61 | RA76 | ||

| Gross volume | Liter | 150 | 250 | 350 | 450 | 650 | 820 | 1220 | 1550 |

| Usable volume (net) | Liter | 105 | 175 | 250 | 310 | 450 | 550 | 870 | 1100 |

| Engine Power max. | kW | 1,9 | 2,5 | 3 | 3 | 7 | 7 | 7 | 11 |

| Outer diameter (A) | mm | 1150 | 1220 | 1420 | 1480 | 1780 | 1850 | 2050 | 2200 |

| Width of strainer surface (B) | mm | 265 | 285 | 370 | 400 | 475 | 490 | 500 | 575 |

| Width of canal (C) | mm | 230 | 260 | 330 | 360 | 440 | 450 | 460 | 530 |

| Total height (D) | mm | 1165 | 1210 | 1280 | 1310 | 1410 | 1500 | 1770 | 1820 |

| Output height (E) | mm | 950 | 1000 | 1030 | 1040 | 1090 | 1170 | 1370 | 1420 |

| Supply height (F) | mm | 650 | 650 | 650 | 650 | 650 | 650 | 700 | 700 |

RM Circular Vibrators

Versatile and efficient

-

Flexible use thanks to a work container without a central dome

-

Homogeneous and uniformly grinding pattern

-

Particularly suitable for hard-to-reach places and difficult geometries

-

Grinding, polishing and high-gloss compaction possible in one machine thanks to the adjustable motor configuration

Application Areas

-

Grinding, polishing and high-gloss compaction of aluminum components

-

Polishing of casting molds

-

Grinding and polishing of medical implants

-

Smoothing of wrought forms and turbine blades

-

Deburring of complex geometries

-

Numerous other possible applications thanks to a process tailored to customer needs

Advantages

-

Consistent and reproducible processing quality of the grinding and polishing results

-

Homogeneous and uniformly grinding pattern

-

Possibility to maintain difficult workpiece contours

-

Best results even in difficult places

-

Possibility of non-contact grinding of several workpieces in one work container

-

Designed for continuous operation even in 24-hour operation

-

Semi-automatic operation possible through electronic process control

Accessories RM Circular Vibrators

-

Additional third unbalance motor at the tank bottom

-

Drive with variable speed control (frequency controlled)

-

PLC controlled electrical switchgear for partially and fully automated plant operation and optimized process control

-

Dosing systems for process media and additives

-

Noise-reducing lids

-

Various clamping systems for fixing workpieces in the work container

-

Extended process water control concepts

-

Additional accessories (upon request)

Technical Data

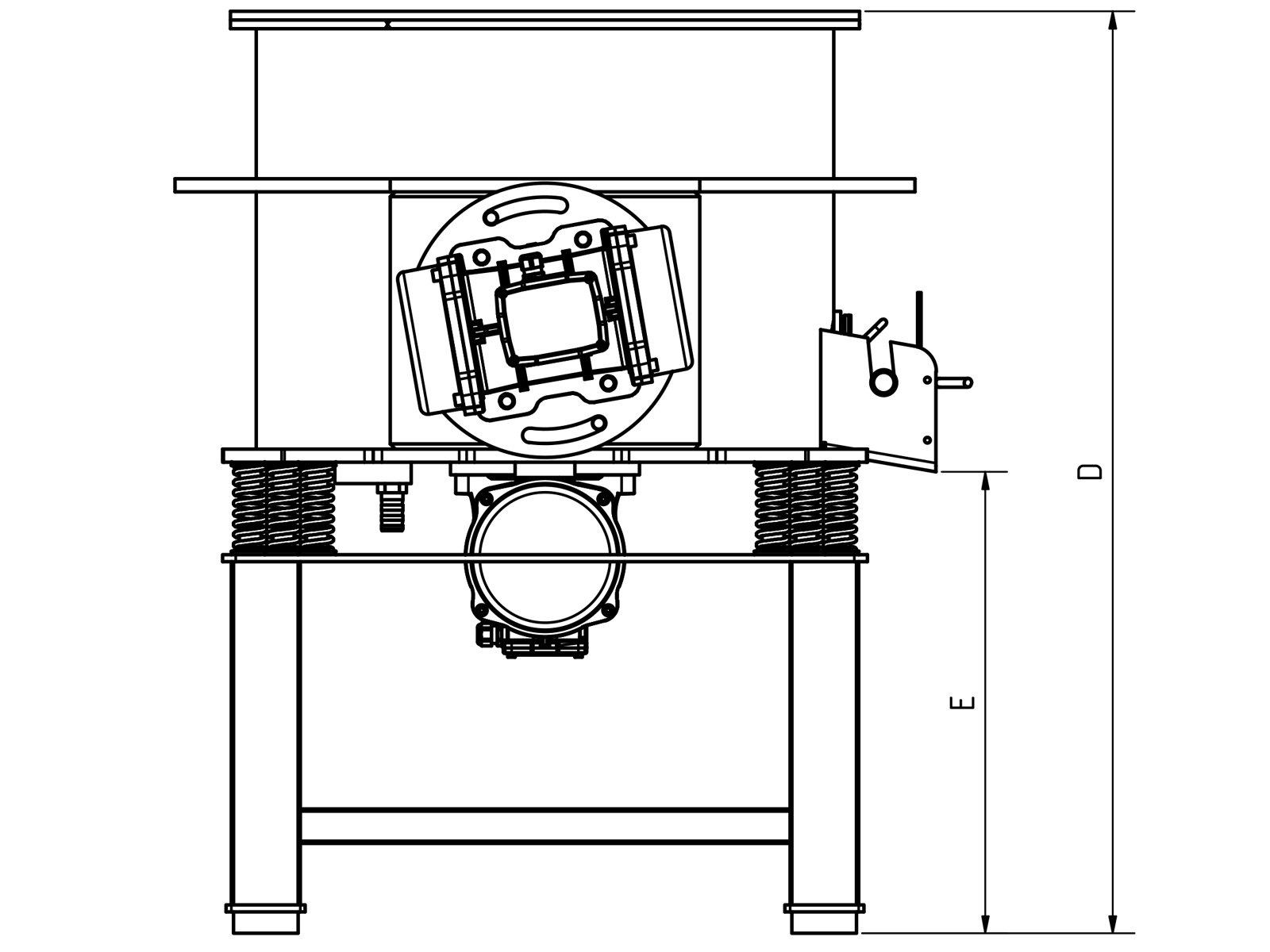

| RM33 | RM34 | RM54 | RM84 | ||

| Gross volume | Liter | 145 | 165 | 260 | 650 |

| Net volume | Liter | 130 | 150 | 240 | 610 |

| Engine Power | kW | 3 | 3 | 5 | 12 |

| Total width (A) | mm | 1260 | 1260 | 1600 | 2100 |

| Inner diameter (C) | mm | 620 | 620 | 750 | 1050 |

| Total height (D) | mm | 1075 | 1140 | 1200 | 1350 |

| Output height (E) | mm | 530 | 530 | 530 | 530 |

TV Trog Vibrators

The all-rounder among the vibratory finishing systems

Compact and Universal

-

Universally applicable in numerous application scenarios

-

Compact design for large work containers

-

Numerous accessories options

-

Particularly inexpensive even for occasional use

-

Fast change of grinding media

-

TV15 and TV25 available as a mobile version (TV15-M and TV25-M)

Application Areas

-

Deburring, smoothing and polishing

-

Descaling, rust removal and cleaning

-

edge rounding

-

Surface finishing

Advantages

-

Scraper edge to reduce workpiece buildup on the inside of the container

-

Particularly economical even for occasional use

-

Optionally available as a version for pressure deburring and for ball polishing

-

Robust construction with a low-maintenance vibration motor. Lifetime greasing.

-

Integrates holder for lifting and moving the machine using a pallet truck or a forklift

-

Fast container emptying and grinding tool change through a generous drain opening for grinding media

-

Quick change drain strainer made of polyurethane

-

Rubber dampened feet to reduce vibration transmission

Accessories TV Trog Vibrators

-

Drive with variable speed control (frequency controlled)

-

PLC controlled electrical switchgear for partially and fully automated plant operations

-

Partitions for dividing the work container

-

Clamping systems for fixing workpieces

-

Dosing systems for process media and additives

-

Noise-reducing lids

-

Extended process water control concepts

-

Screening plants for the separation of workpieces and grinding media

-

Universally screw able and therefore exchangeable delivery chutes

Technical Data

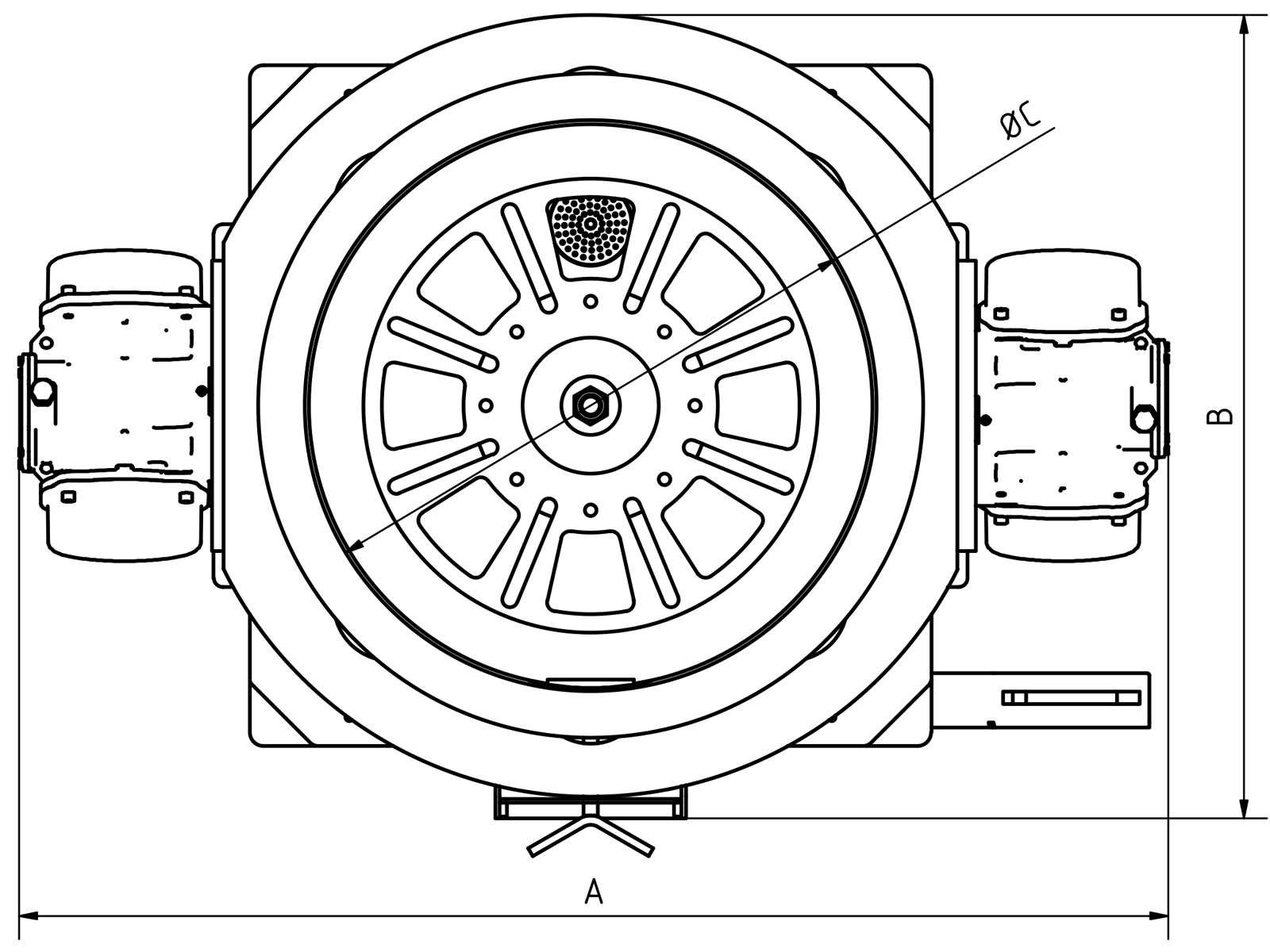

| TV15 | TV25 | TV45 | TV55 | TV73 | TV85 | TV95 | ||

| Gross volume | Liter | 27 | 50 | 115 | 275 | 430 | 840 | 1700 |

| Net volume | Liter | 18 | 36 | 90 | 230 | 370 | 740 | 1550 |

| Engine Power | kW | 0,35 | 0,4 | 1 | 2 | 4 | 5 | 7 |

| Inside length (A) | mm | 500 | 600 | 850 | 1200 | 1100 | 1500 | 2000 |

| Inside width (B) | mm | 220 | 280 | 380 | 480 | 680 | 780 | 980 |

| Inside height (C) | mm | 270 | 325 | 395 | 530 | 650 | 800 | 1000 |

| Outside height (E) | mm | 615 | 615 | 635 | 635 | 635 | 700 | 750 |

TV-M Mobile Trough Vibrators

The mobile trough vibrator for vibratory grinding

Mobile and universal

-

Mobile vibratory finishing machine with integrates preparation of process liquids

-

Integrates strainer box for separating workpiece and grinding tools

-

Compact design for large work containers including sound insulation

-

Plug & Play System: Plug in the 230V power supply and get started

Advantages

-

Mobile use: All components are integrated in a trolley

-

Plug & Play: For commissioning only the 230V power supply has to be plugged in

-

Quiet operation due to sound insulation

-

Integrated electrical control for process monitoring

-

Strainer device for separating workpieces and grinding tools

-

Process water treatment through an integrates filter cascade

Accessories TV-M Mobile Trough Vibrators

-

Drive with variable speed control (frequency controlled)

-

Extended process control by timer

-

Partitions for dividing the work container

-

Clamping systems for fixing workpieces

-

Dosing systems for process media and additives

-

Extended process water control concepts

-

Strainer for separating workpieces and grinding media in different perforations

-

Additional accessories (upon request)

Technical Data

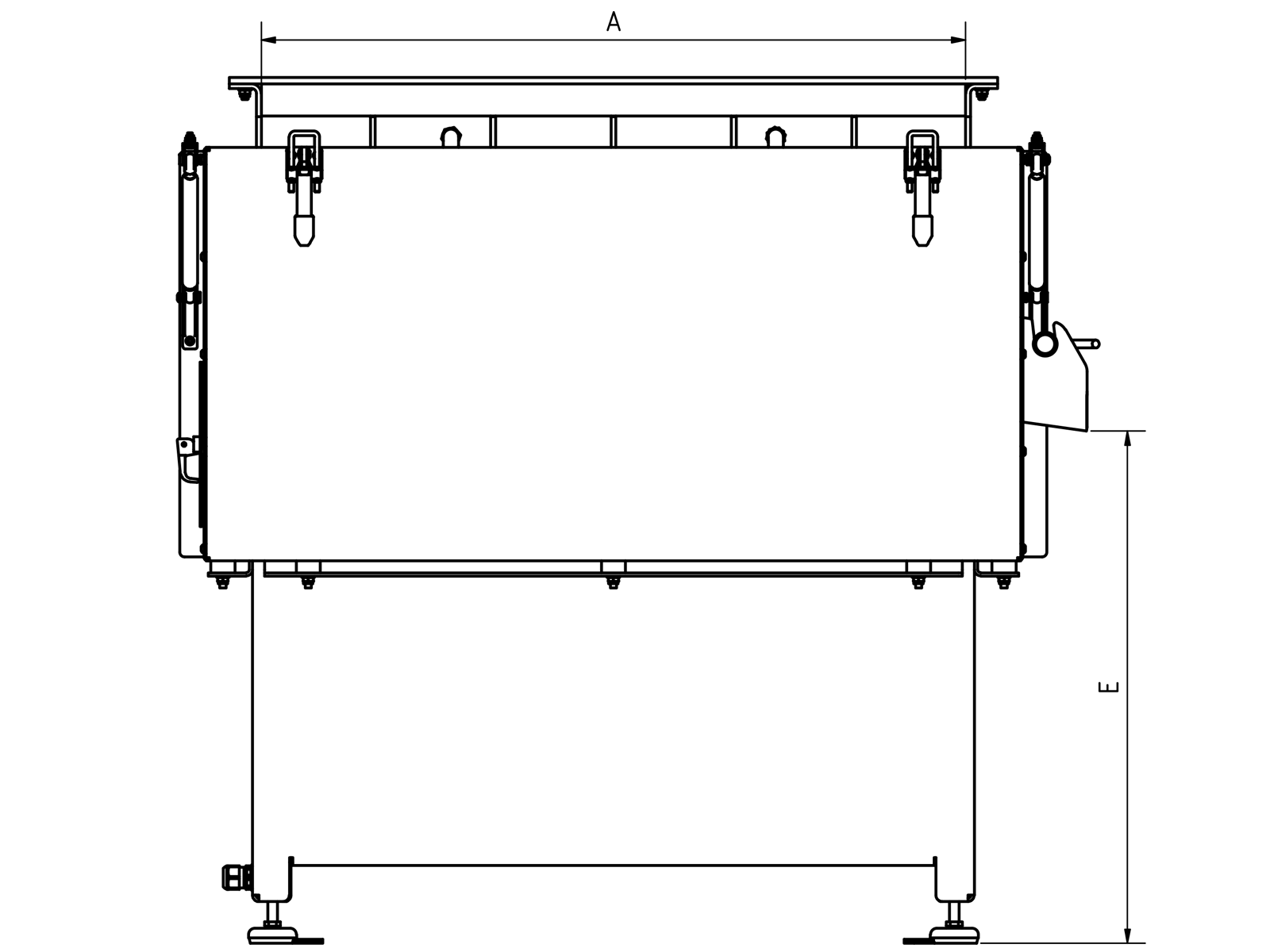

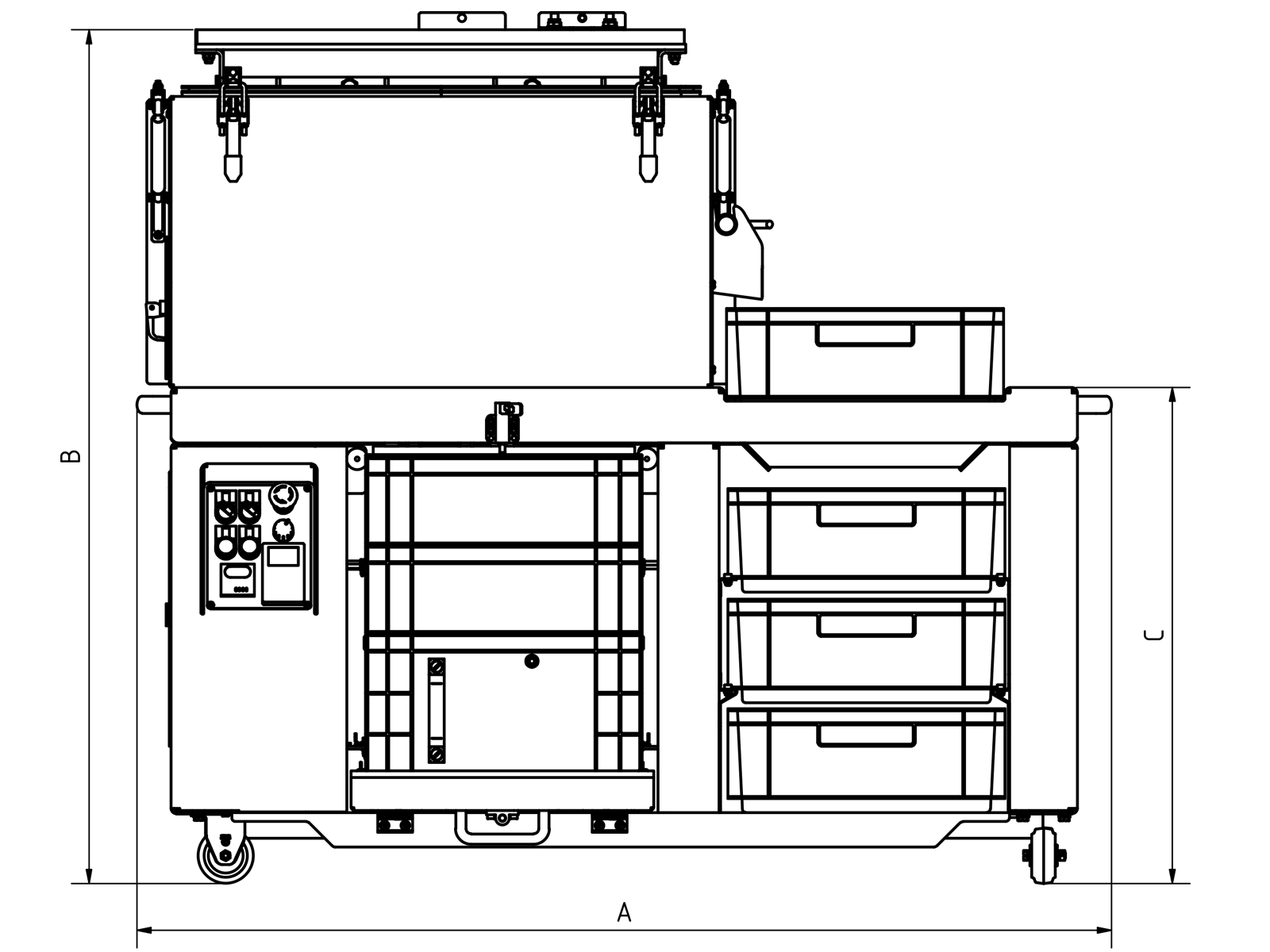

| TV15-M | TV25-M | ||

| Gross volume | Liter | 27 | 50 |

| Net volumen | Liter | 18 | 36 |

| Total power | kW | 0.35 | 0.4 |

| Inside length | mm | 500 | 600 |

| Inside width | mm | 220 | 280 |

| Inside height | mm | 270 | 325 |

| Outside length (A) | mm | 1450 | 1450 |

| High of the tumbler (B) | mm | 1240 | 1240 |

| High of the table (C) | mm | 720 | 720 |

| Width open door (D) | mm | 1200 | 1200 |

| Width closed door (E) | mm | 730 | 730 |

| Total hight (F) | mm | 1350 | 1350 |

RT Circular Dryers

The efficient component drying after mass finishing

Energy-Efficient and Powerful

-

Efficient thanks to optimized heating and covers

-

Drying of components mostly in one pass

-

Universal use of different drying media

-

Spiral flat ramp

-

Protective cover and suction for dust reduction optionally available

Application Areas

-

Component drying directly after the surface grinding process

-

Polishing of components

-

Stain reduction

-

Fine machining of particularly difficult contours

-

Prevention of flash rust due to completely dried surfaces

-

Efficient drying of complex geometries

Advantages

-

Economical and fast drying of components after vibratory finishing

-

Achievement of stain-free surfaces

-

Drying and polishing of workpieces in one operation

-

Integrated sieve section for efficient workpiece separation

-

Depending on the design, simultaneous batchwise operation and continuous operation possible through a built-in flap

-

Spirally rising container bottom for gentle processing without steep ramp

-

Modular exchangeable screen feeders and discharge chutes for flexible use

-

Heating registers mounted as standard in the vibration-decoupled underframe for maximum service life

-

Prepared as standard for connection to dust extraction systems

Accessories for RT Circular Dryers

-

Drive with variable speed control

-

PLC controlled electrical switchgear for partially and fully automated plant operations

-

Pneumatically activated separation flap

-

Dust covers and dust extraction systems

-

Noise-reducing lids

-

Increased heating power for shorter heating times

-

Thermostat-controlled temperature control

-

Universally adaptable delivery chutes

-

Wear and shock protection coatings

-

Strainer for separation in different perforation sizes and with protective coatings to minimize noise and component damage

Technical Data

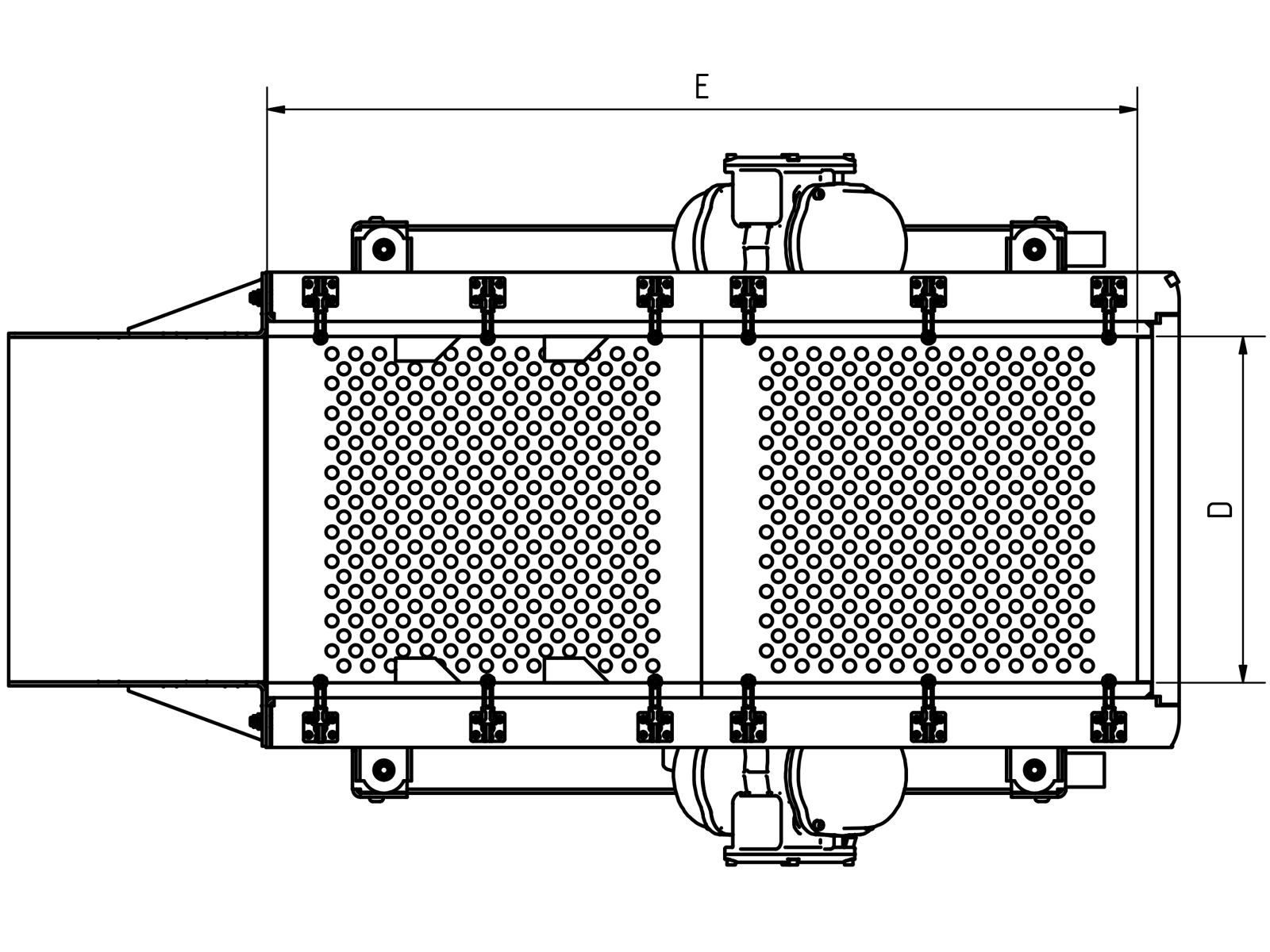

| RT20 | RT27 | RT37 | RT41 | RT55 | ||

| Gross volume | Liter | 150 | 270 | 580 | 850 | 1600 |

| Net volume | Liter | 80 | 140 | 350 | 450 | 750 |

| Engine Power | kW | 1,6 | 1,6 | 1,9 | 2,5 | 5 |

| Max. heating capacity | kW | 3 | 4 | 6 | 10 | 14 |

| Outer diameter (A) | mm | 1050 | 1200 | 1650 | 1900 | 2200 |

| Width of strainer surface (B) | mm | 250 | 330 | 450 | 500 | 670 |

| Width of canal (C) | mm | 252 | 330 | 450 | 500 | 670 |

| Total height* (D) | mm | 1050 | 1100 | 1250 | 1350 | 1400 |

| Output height* (E) | mm | 820 | 850 | 900 | 950 | 1000 |

| Supply height* (F) | mm | 820 | 850 | 950 | 980 | 1050 |

*custom height adjustment possible

|

||||||

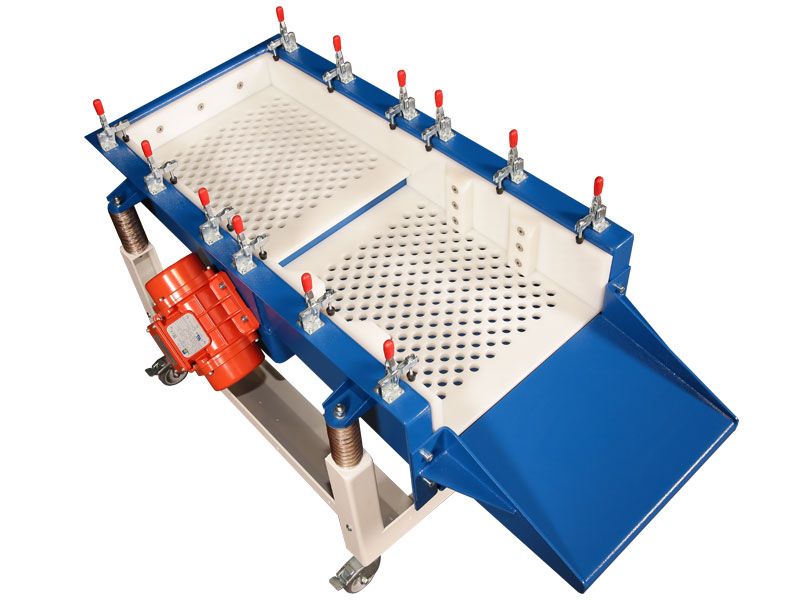

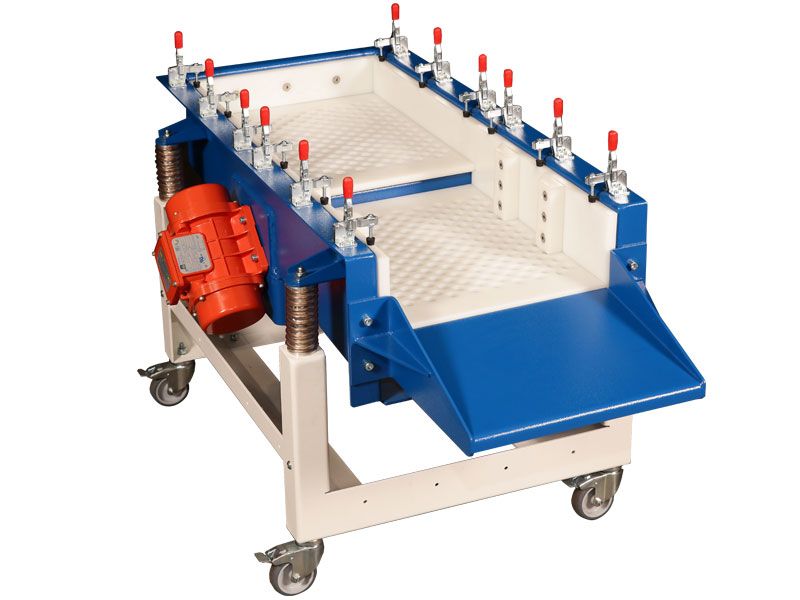

WS Separators

For Economical and Mobile Separation

Economical and Mobile

-

Economic separation of workpieces and grinding media

-

Modularly combinable with many slide grinding systems

-

Quickly exchangeable screen inserts for a wide range of grinding media

-

Mobile use thanks to lockable rollers

-

Adaptable to a wide variety of vibratory grinding machines

Advantages

-

Semi-automatic operation by two unbalance motors

-

Economical separation of workpieces and grinding tools even with larger quantities

-

The shortest set-up times when changing the sieve plates are made possible by a tool-free quick clamping system

-

Integrated drop stages for improved sieving of grinding wheels

-

Conical perforated screens to avoid wedged grinding wheels

-

Sieve pan made of stainless steel, therefore no spreading of rust traces

-

Screen surface completely lined with plastic to reduce damage to components during the screening process

Additional Equipment WS Separators

-

Drive with variable speed control

-

Electronic connection within a plant

-

Sieve plates in various perforations depending on customer requirements

-

Dispensing chutes in various designs and lengths

-

Integrated screening of undersize chips

-

Scraper, rinsing rings and drop steps for improved separation

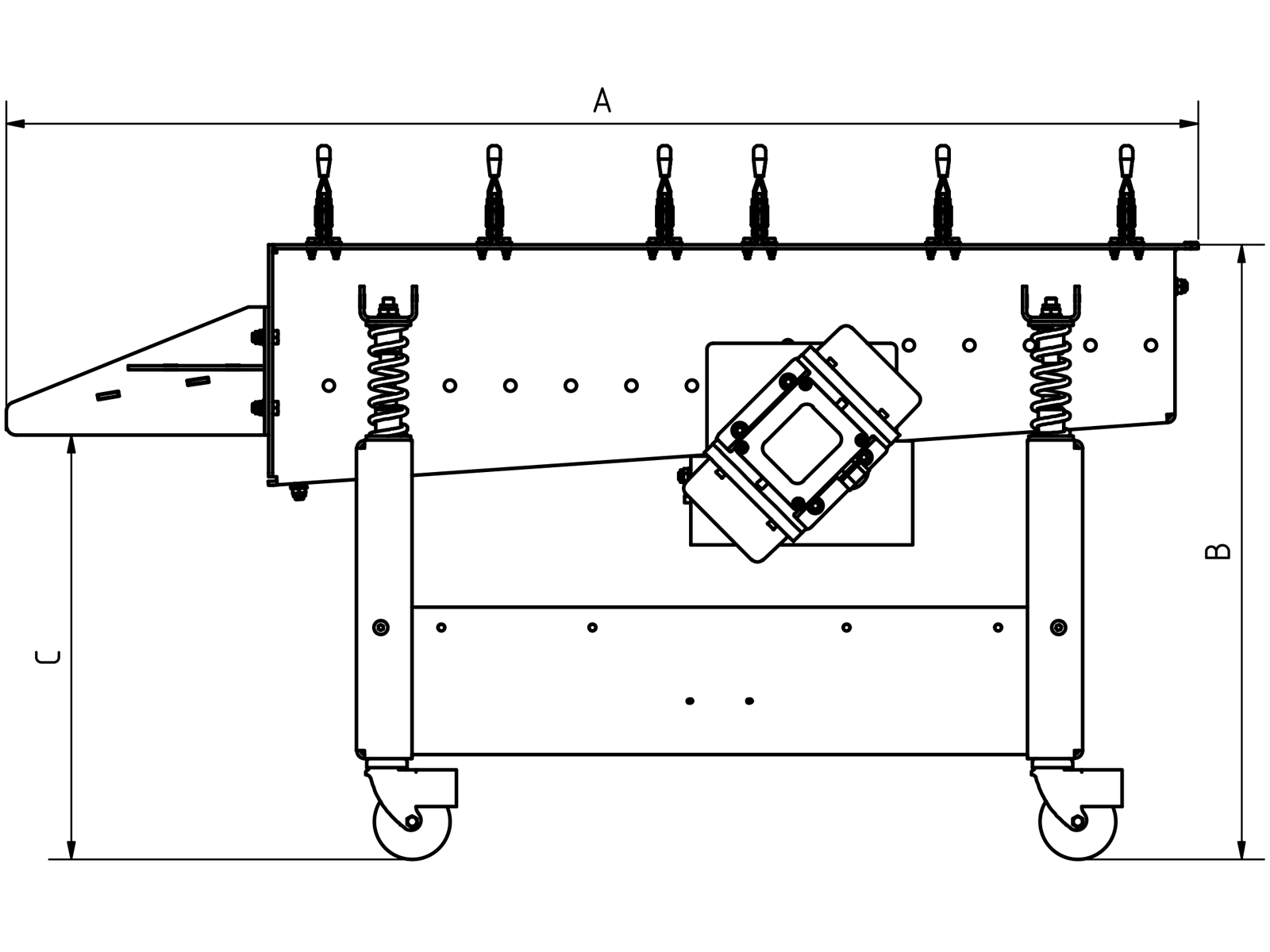

Technical Data

| Engine Power | kW | 2 x 0,12 | 2 x 0,16 | 2 x 0,16 | 2 x 0,35 |

| High of component-supply* (B) | mm | 610 | 650 | 650 | 700 |

| Output height* (C) | mm | 420 | 420 | 420 | 420 |

| Width of the strainer (D) | mm | 350 | 350 | 500 | 600 |

| Length of the strainer (E) | mm | 880 | 1300 | 1200 | 1400 |

*Custom height adjustment possible

|

|||||

Small Bowl Vibratory Machines

Technical Data

| Description | KVM 15 | KVM 40 | KVM 120 |

| Total volume L | 18 | 43 | 130 |

| Internal diameter of the bowl mm | 410 | 565 | 852 |

| max. parts size mm | 90 | 120 | 160 |

| PU-layer bottom mm | 10 | 10 | 15 |

| PU-layer side wall mm | 8 | 8 | 12 |

| Motor kW, 380 V/ 50 Hz | 0,17 | 0,37 | 1,1 |

| Max. speed rpm | 1500 | 1500 | 1500 |

| Total hight mm | 620 | 780 | 890 |

| Total weight kg | 42 | 100 | 225 |

| Dosing pump | yes | yes | yes |

| Controll box incl. frequency converter | 1000-1500 | 1000-1500 | 1000-1500 |

Small Trough Vibratory Machines

TECHNICAL DATA

| Description | TVM 15 | TVM 40 | TVM 100 |

| Total volume L | 18 | 53 | 130 |

| External dimension mm | 630x300x500(h) | 790x415x670 (h) | 1280x890x920 (h) |

| Inside dimension mm | 500x200x200 (h) | 590x290x290 (h) | 1000x380x410 (h) |

| Motor kW, 380 V/ 50 Hz | 0,18 | 0,55 | 1,1 |

| PU-layer bottom mm | 10 | 10 | 15 |

| PU-layer side wall mm | 8 | 8 | 10 |

| Speed control max. rpm | 1500 | 1500 | 1500 |

| Total weight kg | 50 | 80 | 300 |

| Dosing pump | yes | yes | yes |

| Switch direction of rotation (left/right) | yes | yes | yes |

| Control box incl. frequency converter | 1000-1500 | 1000-1500 | 1000-1500 |

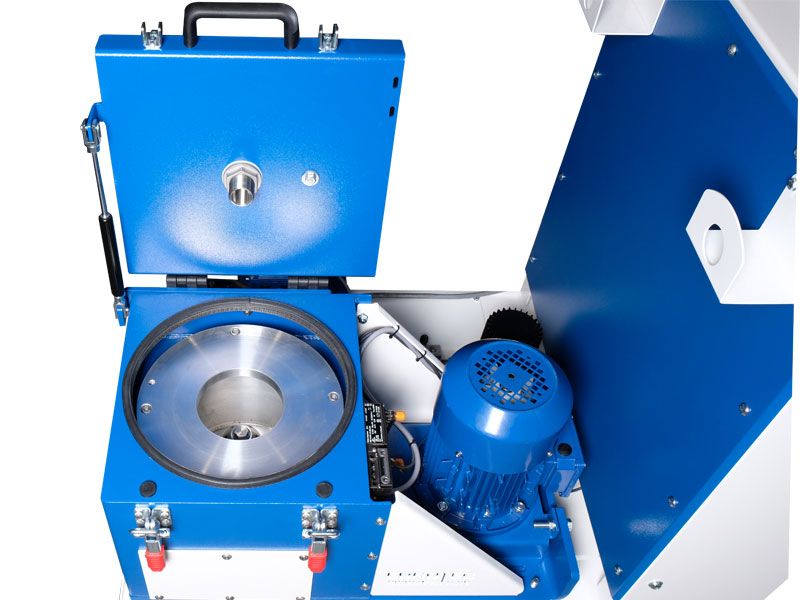

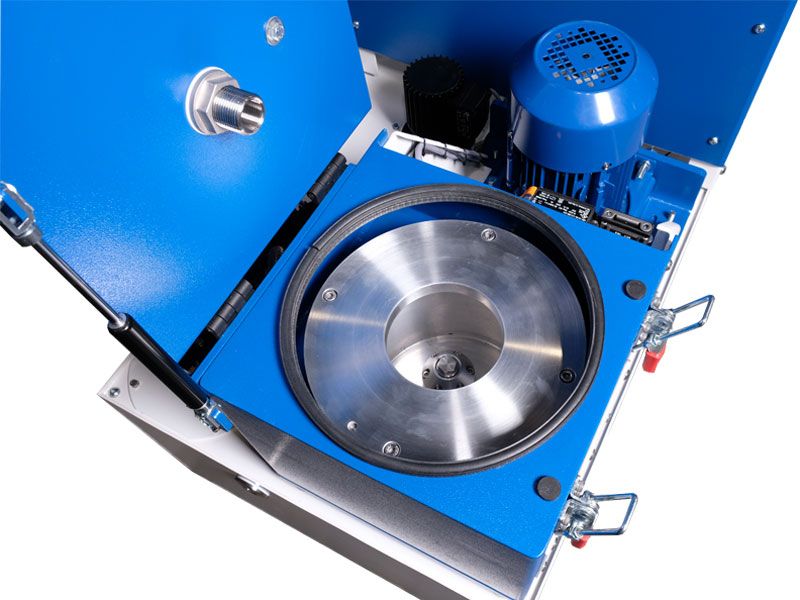

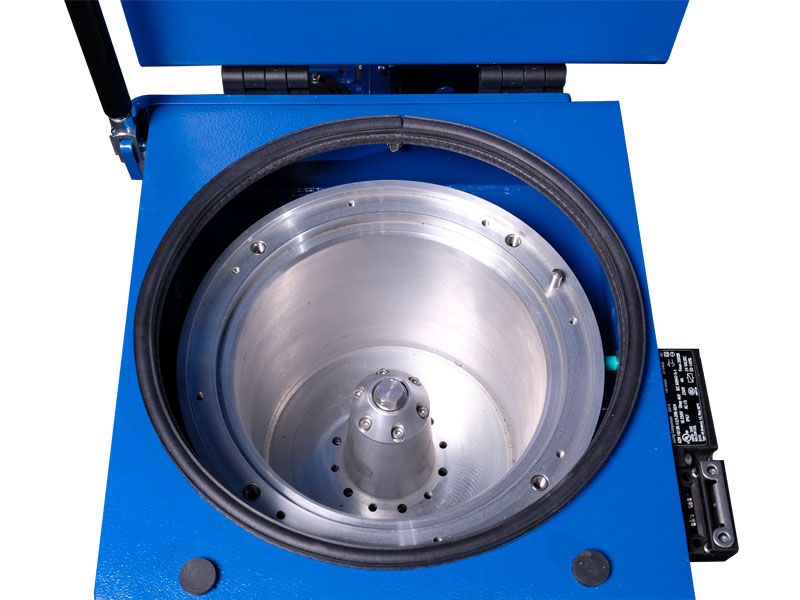

Centrifugal Finishing Machines

Technical Data

| Description | KSM 18 | KSM 60 |

| Tola volume L | 21 | 63 |

| Internal diameter of the bowl mm | 340 | 520 |

| max. part size mm | 30×30 | 50×50 |

| Motor kW, 380 V/ 50 Hz | 0,75 | 2,2 |

| max. speed rpm | 1500 | 1500 |

| Total hight mm | 1000 | 1300 |

| Total weight kg | 120 | 380 |

| Dosing pump | yes | yes |

| Control box incl. frequency converter | 1000-1500 | 1000-1500 |

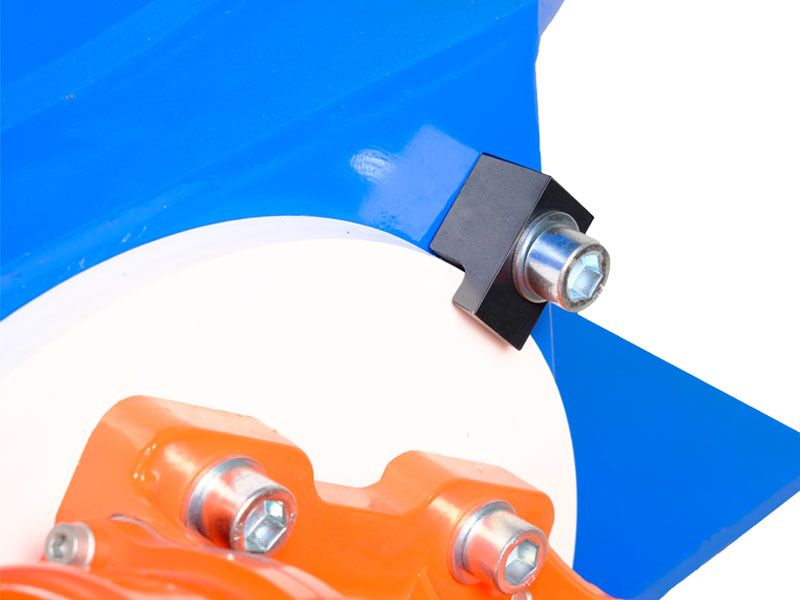

Process Media and Compound

100% tailored to your machining process

-

Numerous different designs available

-

Exactly suitable for your process

-

High grinding performance with a long service life

-

Granules for the efficient drying of your components after surface grinding

Abrasives

-

Ceramic media

-

Plastic media

-

Special media

Granules for Component Drying

-

Corn

-

Nut shells

-

Various special media (high polishing)

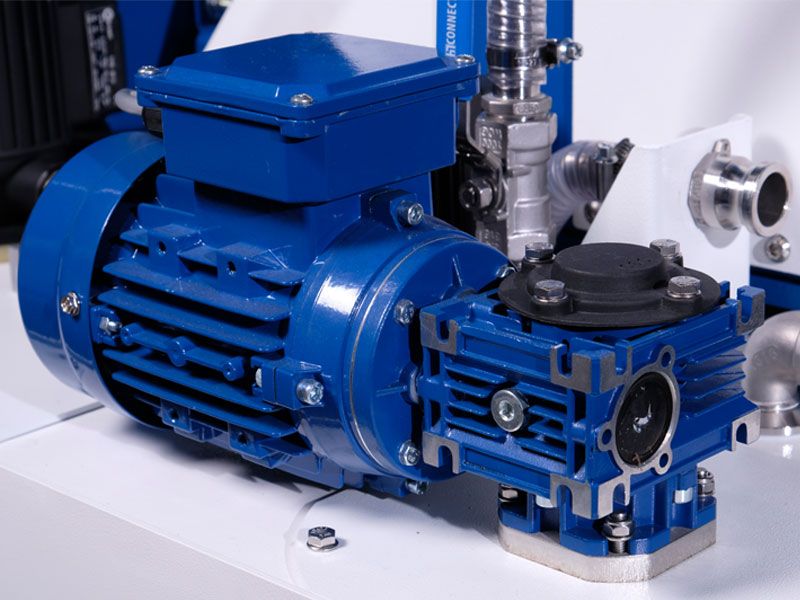

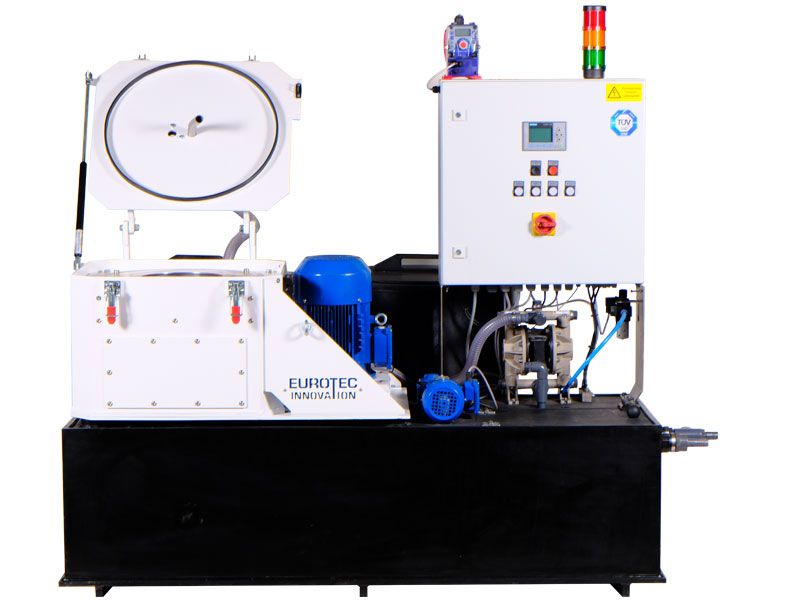

ZS Centrifuges

for Cycle Management of Process Fluids

Environmentally Friendly and Powerful

-

Efficient processing of process liquid through high centrifugal forces

-

Different sizes exactly suitable for your application

-

High throughput enables the simultaneous supply of several systems

-

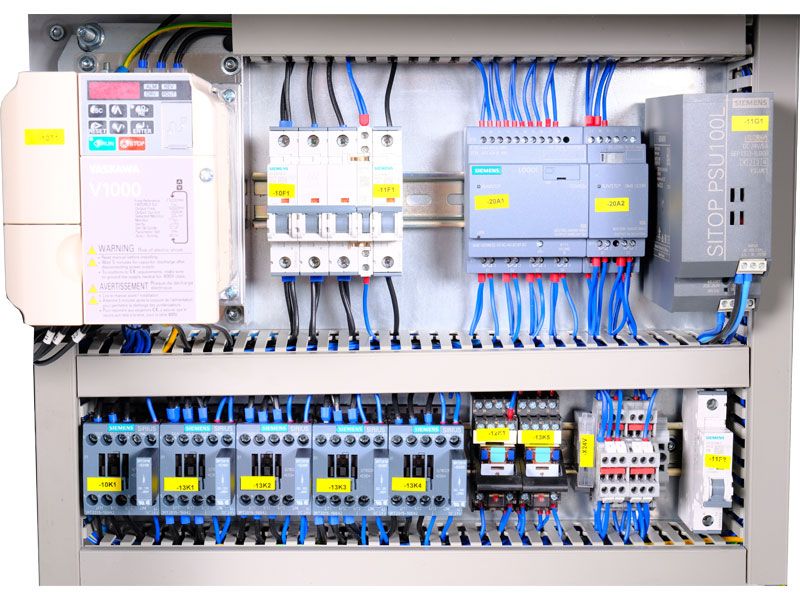

PLC controlled and monitored cleaning process

-

Process water management

Application Areas

-

Treatment of vibratory finishing process water

-

Cleaning of mixtures (suspensions and emulsions)

-

Preparation of phosphating, painting, washing and oil baths

-

Processing of cooling lubricants

-

Preparation of cooling liquids from saws, milling machines and lathes

-

General separation of solids from liquid mixtures

Advantages

-

High discharge capacity due to acceleration forces in the system of over 2000 times gravitational acceleration (depending on model)

-

Management of the process water in a cycle, which minimizes operating costs and protects the environment

-

Saving of expensive additives for the finishing process (compound)

-

Economical and efficient separation of solid particles from a mixture

-

Designed for continuous operation with high availability

-

Complete process water management in one system (buffer storage, pressure pumps, automatic level monitoring and refilling, …)

-

Supply of several systems simultaneously with only one ZS centrifuge by optionally available additional buffer tanks for clear water

-

Suitable for process liquids up to 70 °C (optional cooling available)

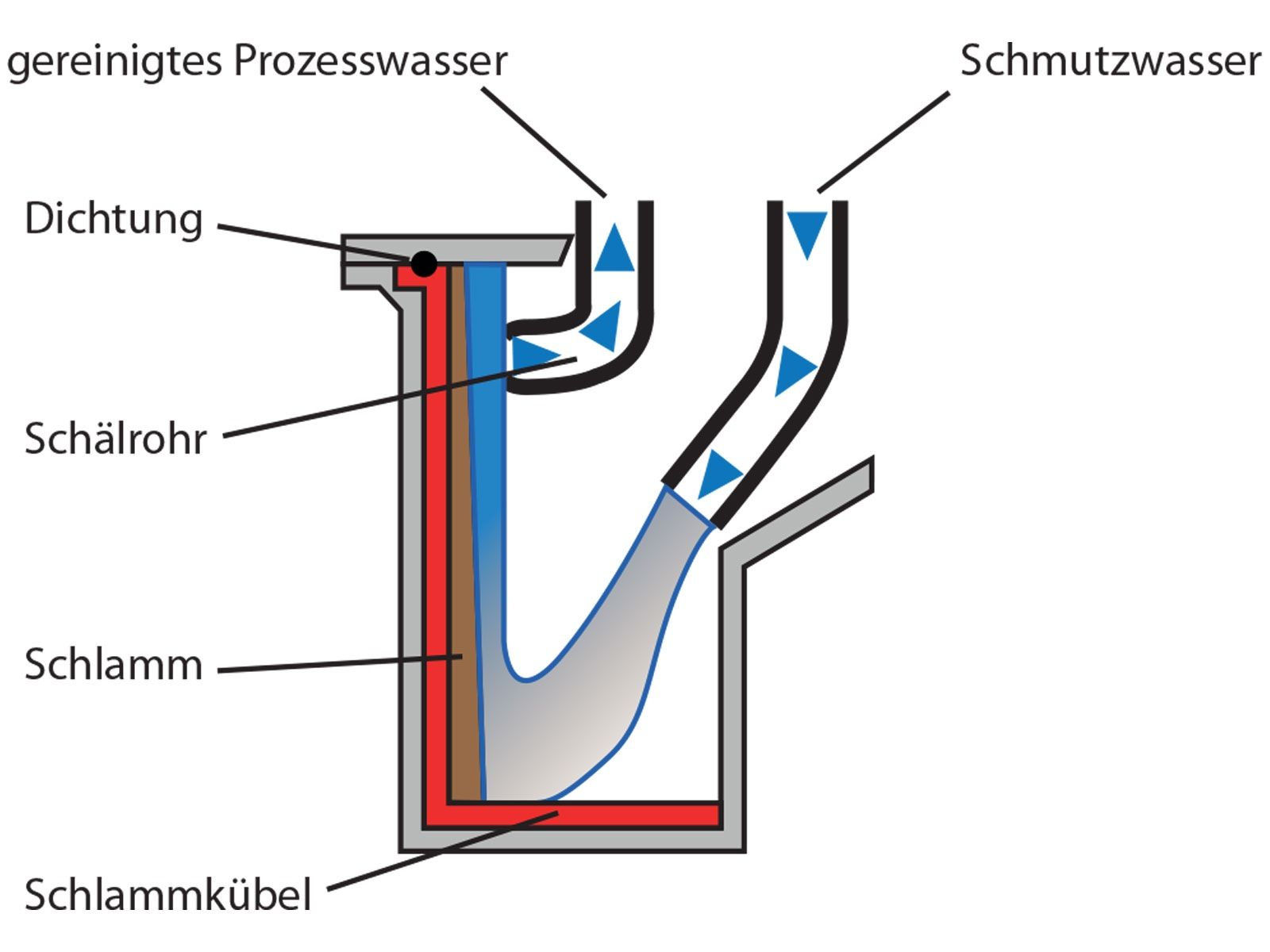

Equipment ZS Zentrifugen

-

Various container sizes as buffers for process fluids made of PE, PP, stainless steel

-

Modularly expandable clear water tank (KW)

-

Peeling pipe for clear water supply without additional feed pump

-

Pressure pumps for the simultaneous supply of process water to several systems

-

Auxiliary pumps and lifting systems for sucking liquid from foreign containers

-

Filter and screening systems for the pre-cleaning of process liquids

-

Electronic coupling with a plant park

-

Automatic level monitoring and refill dosing devices

-

Automated dosing devices for additional media (flocculant, compound)

-

Stainless steel housing (A2 or A4)

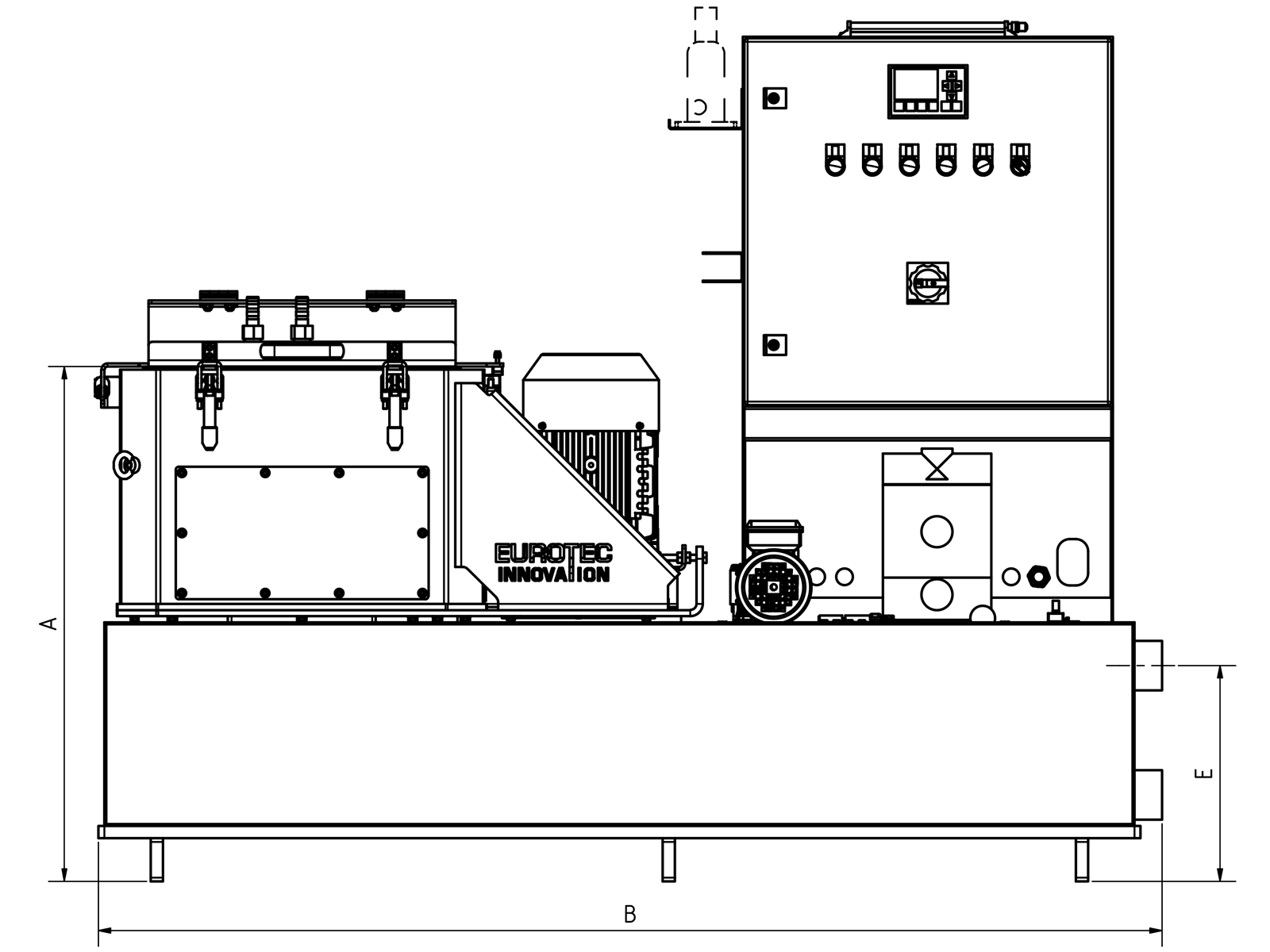

Technical Data

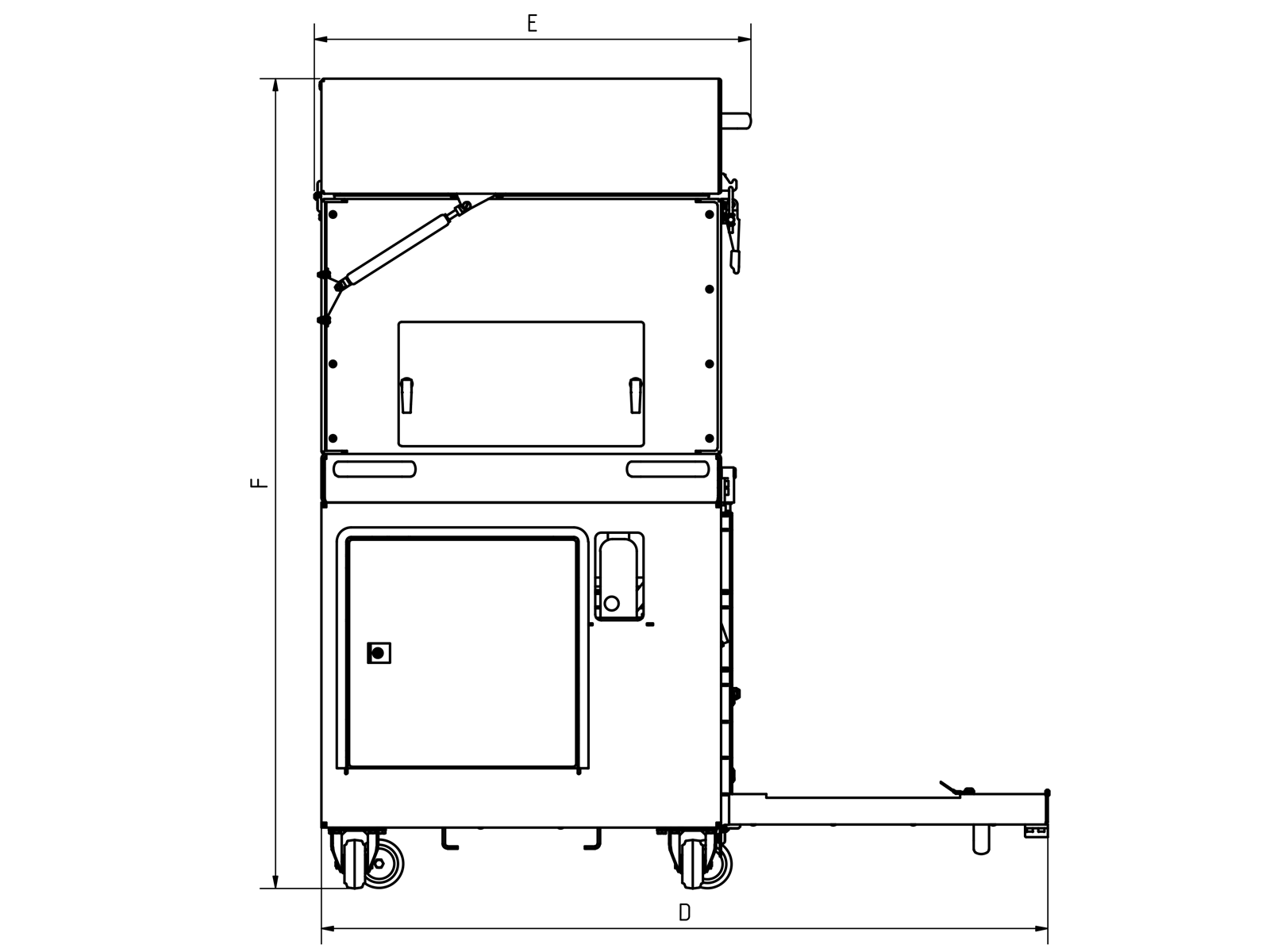

| ZS21 | ZS38 | ||

| Max. Capacity | Liter/Minute | 80 | 120 |

| Max. Capacity of sludge basket | Liter | 3,5 | 15 |

| kg | 5,5 | 22 | |

| Rated speed | RPM | 4160 | 2900 |

| Max. acceleration at nominal speed | g | 2070 | 1810 |

| Drive Power | kW | 1,5 | 4 |

| Average power consumption | kW | 0,8 | 1,5 |

| Internal diameter of the drum | mm | 210 | 380 |

| Dirty water tank | Liter | 200 | 200 |

| Removal height of sludge basket (A) | mm | 790 | 870 |

| Total width (B) | mm | 1740 | 1740 |

| Total height (C) | mm | 1400 | 1400 |

| Total depth (D) | mm | 700 | 700 |

| High of dirt water drain (E) | mm | 375 | 375 |

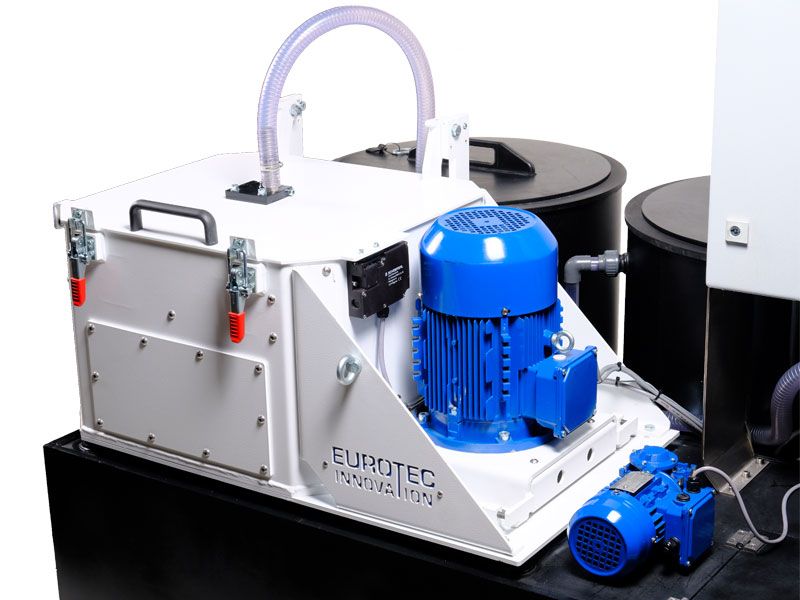

ZS-M Mobile Centrifuges

Mobile and Powerful

-

Mobile cleaning centrifuge with optional integrated tanks for process liquids

-

Plug & Play: ready for operation in just a few minutes

-

Efficient processing of process fluids through high centrifugal forces

-

PLC controlled and monitored process

Application Areas

-

Treatment of vibratory finishing process water

-

Cleaning of mixtures (suspensions and emulsions)

-

Preparation of phosphating, painting, washing and oil baths

-

Processing of cooling lubricants

-

Undersize discharge during wet blasting

-

General separation of solids from liquid mixtures

-

Cleaning of baths and storage tanks from external Systems

Advantages

-

Maximum mobility through the integration of all components on a trolley

-

Flexible use due to a compact design

-

High discharge capacity due to acceleration forces in the system of over 2000 times gravitational acceleration

-

Management of the process water in a cycle, which minimizes operating costs and protects the environment

-

Saving of expensive additives for the finishing process (compound)

-

Economical and efficient separation of solid particles from a mixture

-

Designed for continuous operation with high availability

-

Plug & Play System: ready for use in minutes

-

Clean liquids from multiple machines with just one centrifuge

Equipment ZS-M Centrifuges

-

Clear water tank (KW) with pressure pumps for process water supply

-

Waste water tank (SW) as a buffer for process liquids

-

Combined trolley with several separate containers (clear and waste water)

-

Optionally with or without a peeling pipe for the discharge of clear water

-

Auxiliary pumps for drawing liquid from foreign containers

-

Electronic coupling with a plant park

-

Agitator for improved solids discharge

-

Automatic compound level monitoring and dosing units

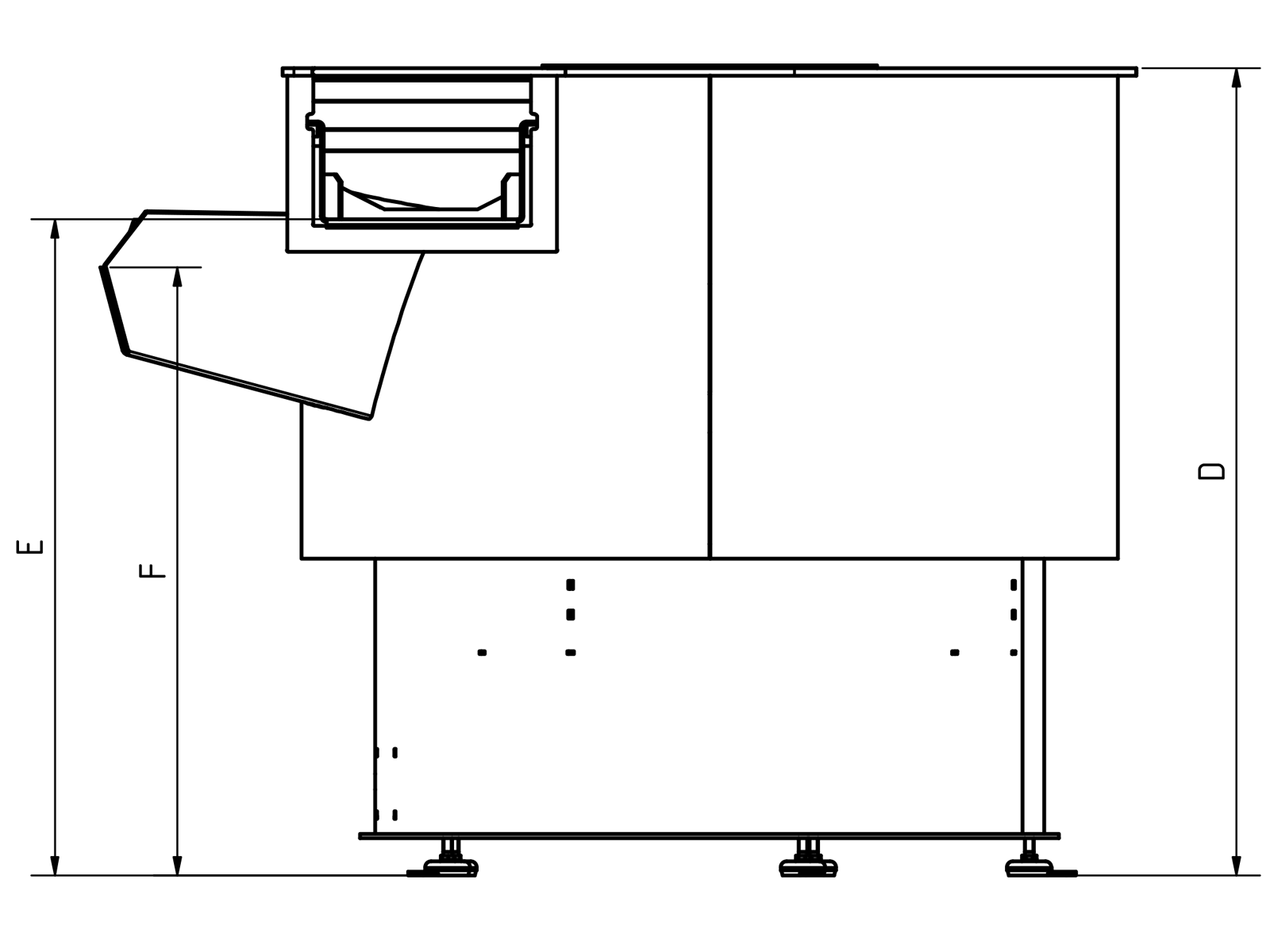

Technical Data

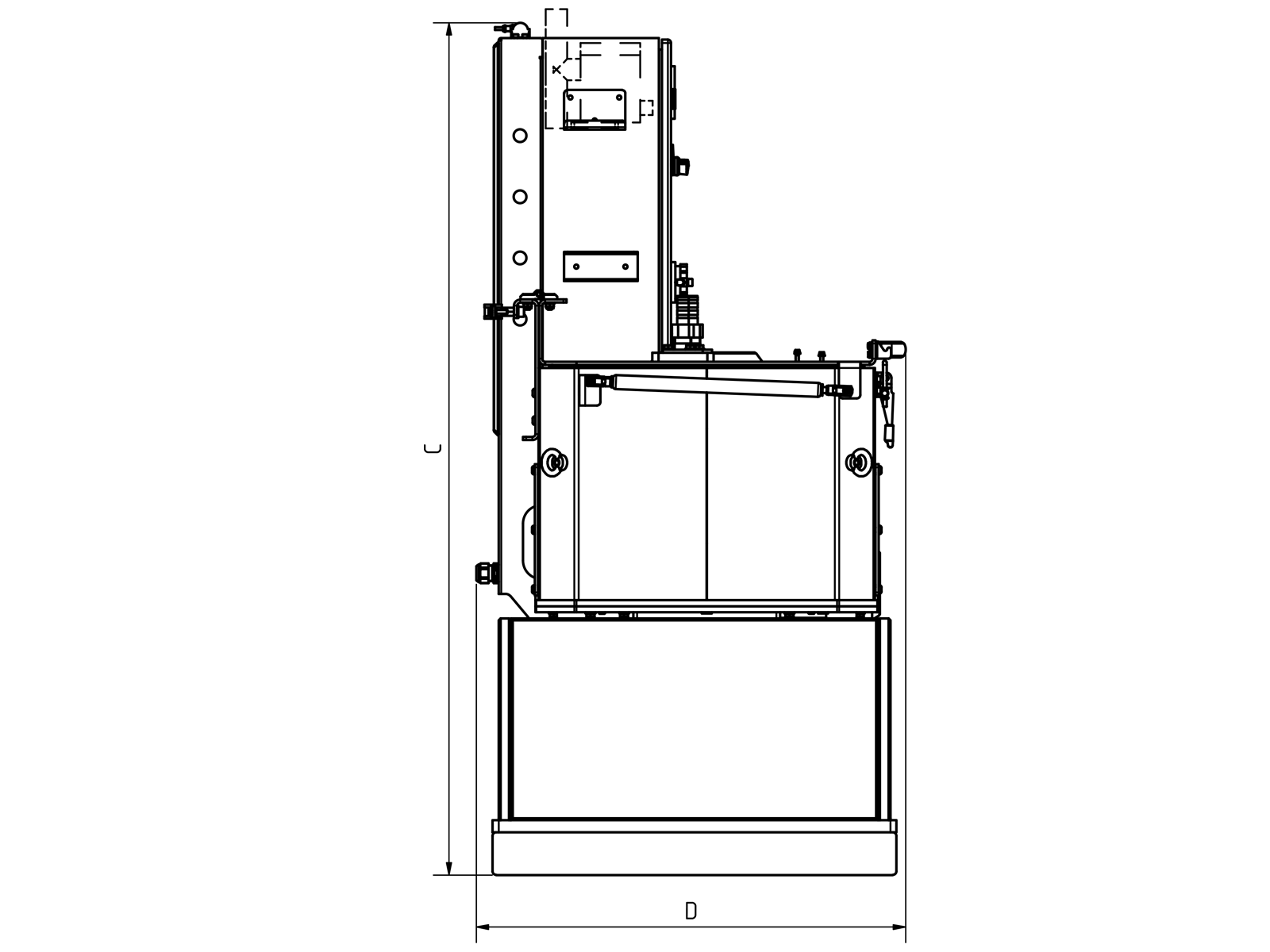

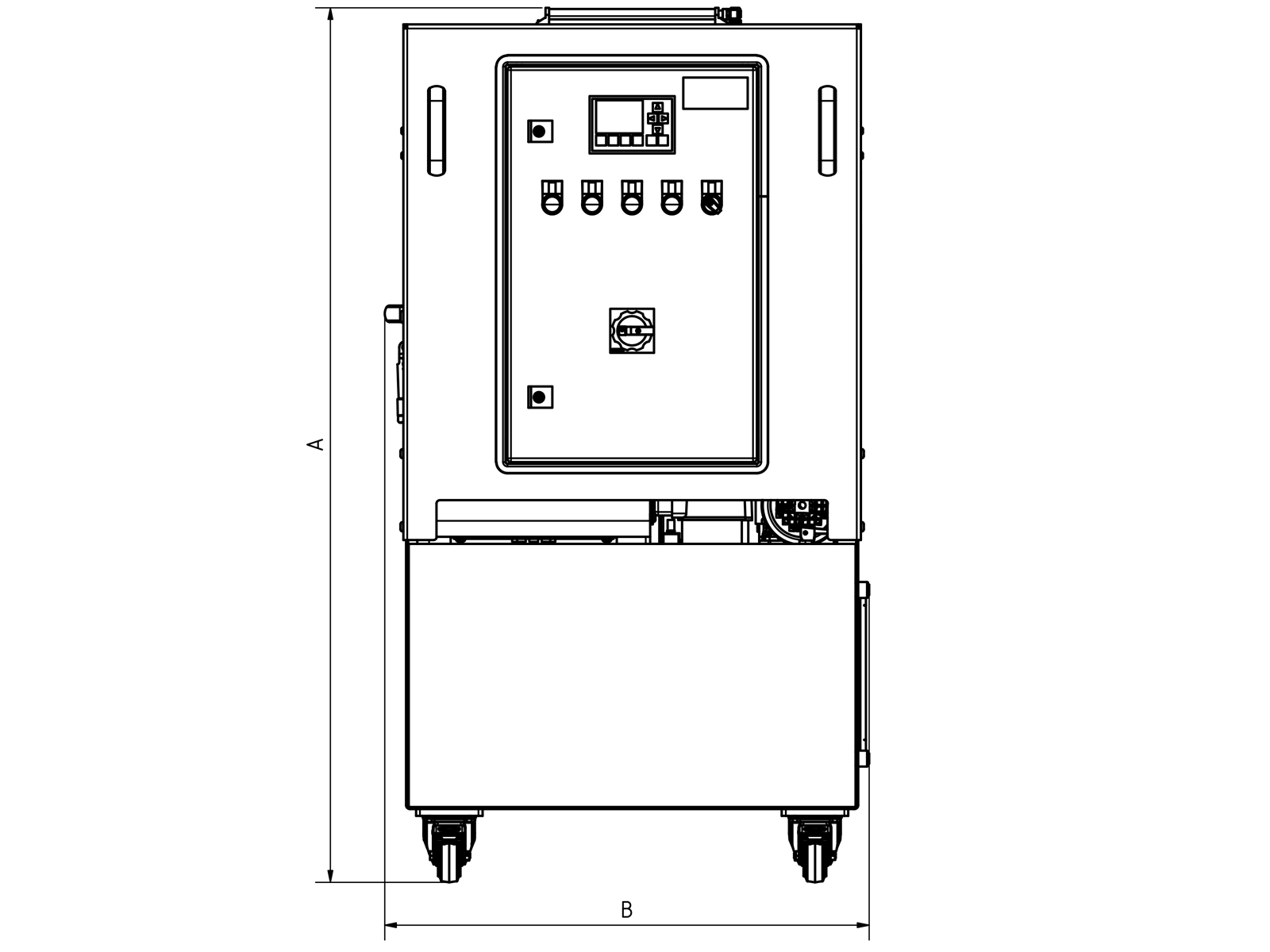

| ZS21-M | ZS21-M | ZS38-M | ZS38-M | ||

| SW+KW | SW | SW+KW | FW | ||

| Max. Capacity | Liter/min | 70 | 70 | 120 | 120 |

| Max. Capacity of Sludge basket | Liter | 3,5 | 3,5 | 15 | 15 |

| kg | 5,5 | 5,5 | 22 | 22 | |

| Rated speed | U/min | 4160 | 4160 | 2900 | 2900 |

| Max. acceleration at nominal speed | g | 2070 | 2070 | 1810 | 1810 |

| Engine power | kW | 1,5 | 1,5 | 4 | 4 |

| Average power consumption | kW | 0,8 | 0,8 | 1,5 | 1,5 |

| Internal diameter of the drum | mm | 210 | 210 | 380 | 380 |

| Dirty water tank | Liter | 99 | 192 | 150 | – |

| Process water tank | Liter | 93 | – | 100 | – |

| Total height (A) | mm | 1330 | 1330 | 1330 | 1330 |

| Total width (B) | mm | 730 | 730 | 980 | 980 |

| High of dirty water drain(C) | mm | 840 | 840 | 920 | 920 |

| Total length (D) | mm | 1030 | 1030 | 1380 | 1380 |